Product test: UniFormation GKtwo

We asked our product tester Lukas to take a close look at three UniFormation devices. In his report, you will find out what he particularly likes about the devices, what he doesn't really like and what suggestions he would have for improvement. Have fun while reading!

UniFormation GKtwo

► The first impression

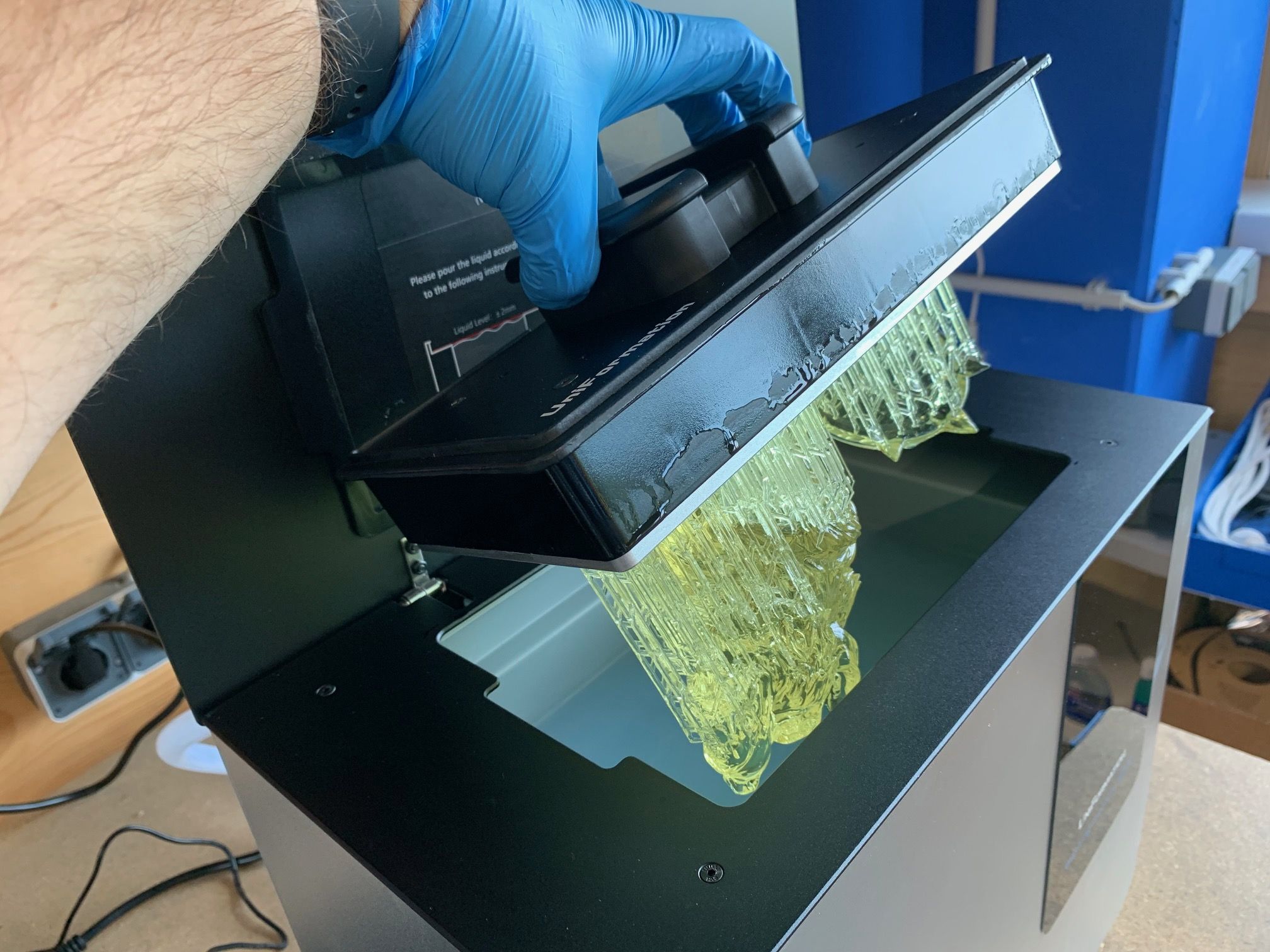

The GKtwo resin printer from UniFormation impressed me right from the start. Thanks to the well-made housing and the solid-looking resin tank, the resin printer immediately makes a robust and stable impression.

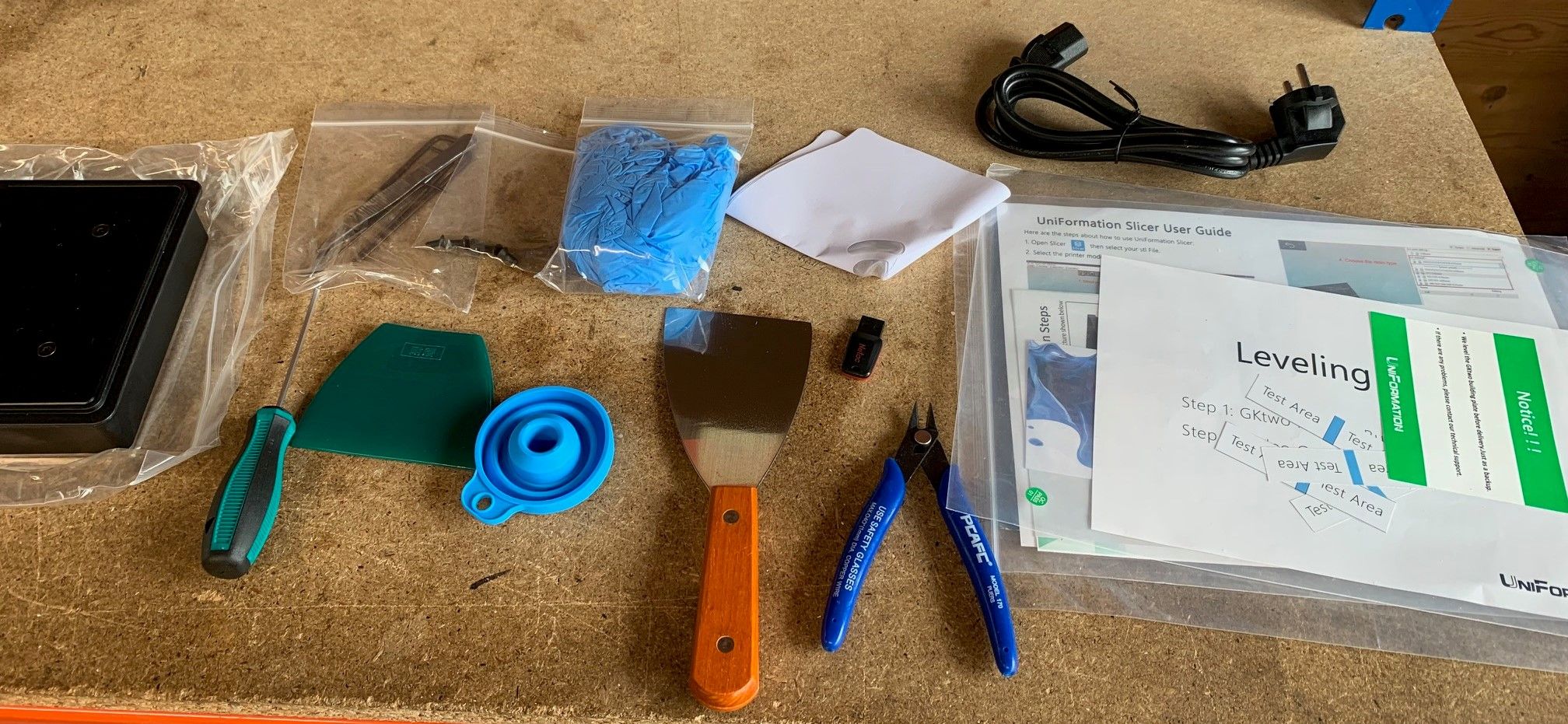

The extensive accessories that are included also make me very excited. The spatula included in the contents of delivery is particularly practical, with which you can easily remove the remaining resin in the tank. Not only does this save you from costly waste of material, but the otherwise time-consuming cleaning after the printing process is also quicker and more effective.

► The Set-up

Setting up the printer went smoothly and was easy to manage.

However, I found that the build plate pre-levelled by UniFormation was not 100% straight, which is quite annoying. The ability to level the printer yourself would be desirable here. To be honest, I have to admit that I didn't bother to think about whether loosening the screws could level the plate, as my printed models still turned out very nice. Unfortunately, in the included leveling description I didn't find any information about how the leveling works exactly.

► The practical design

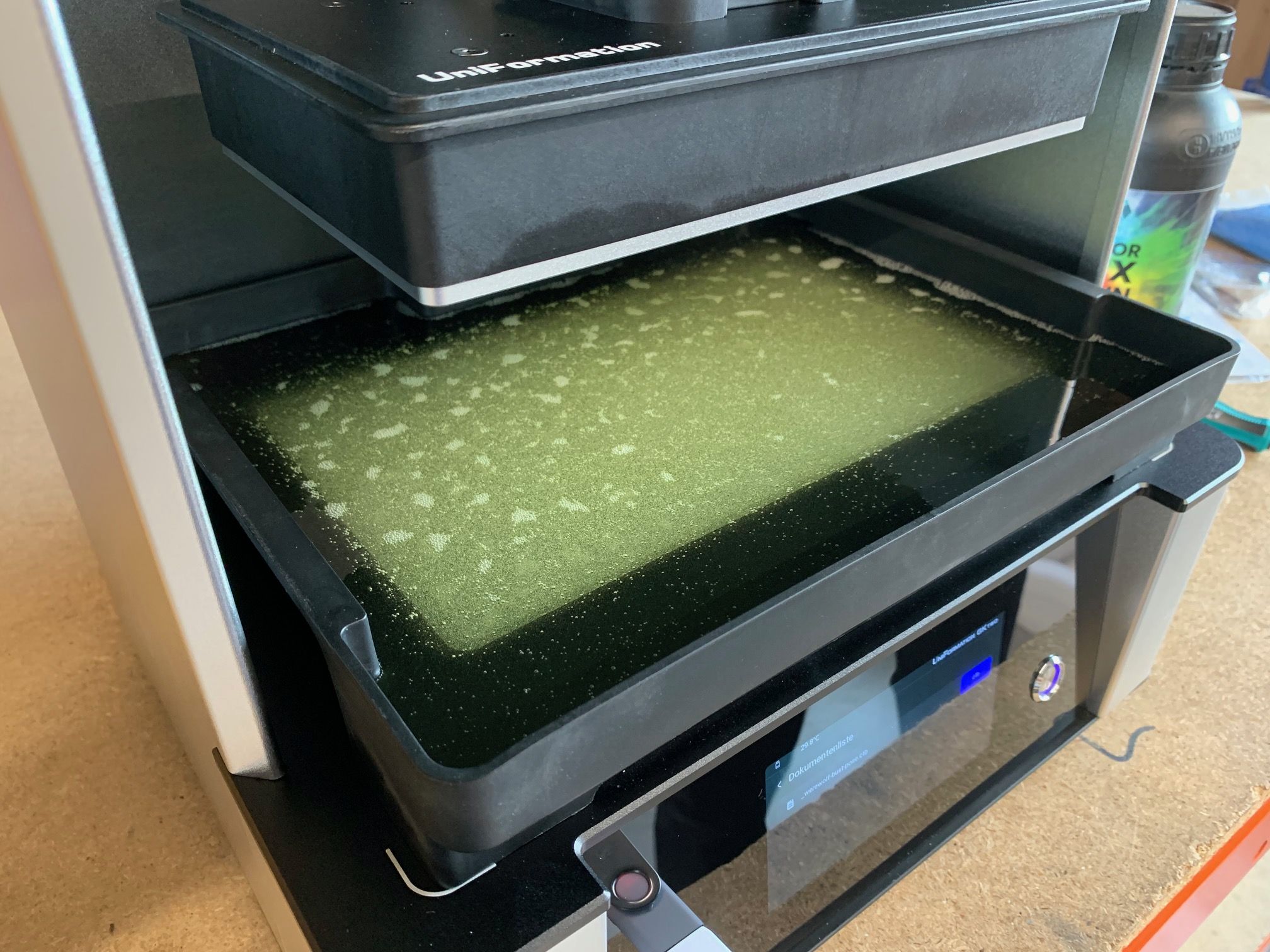

My personal highlight about the GKtwo is the innovative design of its resin tank. Instead of annoying screws that have to be unscrewed and screwed on again for each cleaning, the tank is “plugged in”, so to speak. This makes cleaning the tank extremely easy and saves valuable time.

My personal highlight about the GKtwo is the innovative design of its resin tank. Instead of annoying screws that have to be unscrewed and screwed on again for each cleaning, the tank is “plugged in”, so to speak. This makes cleaning the tank extremely easy and saves valuable time.

The huge tank can be filled with a large amount of resin, which is particularly advantageous for large printing projects. An nFEP film is securely attached to the rear edge of the tank with screws and can be changed with ease. The additional extension of the tank rim is a clever addition that minimises the risk of spills.

However, I am of the opinion that the maximum holding capacity of the resin tank of max. 700 grams could have been emphasised more, as this range must not be exceeded under any circumstances. That's why I almost had a spill.

► The interface

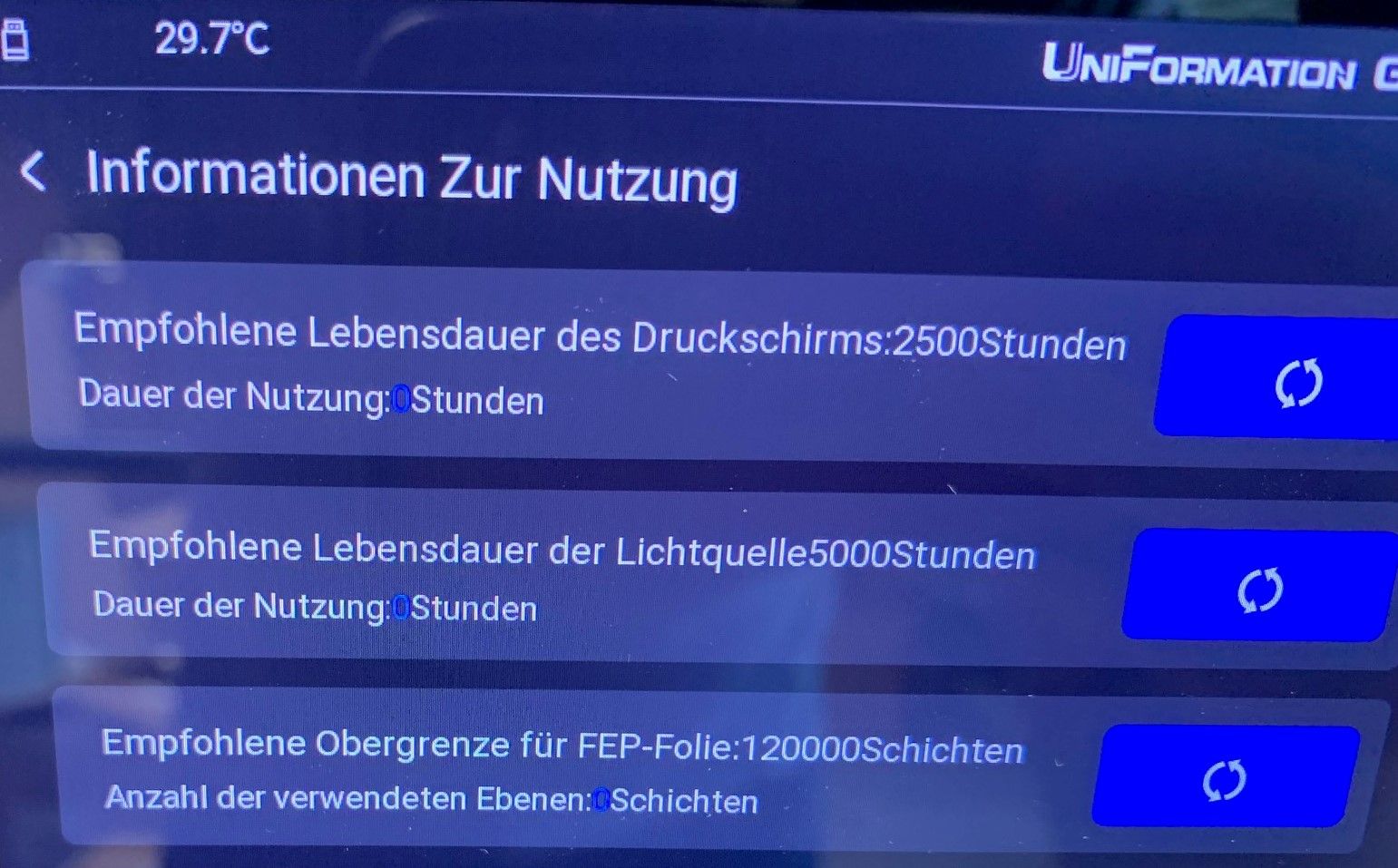

The printer is very easy to use. The menu is intuitively designed and responds perfectly even when wearing gloves. I find the function that allows you to view the printing hours and select the language particularly practical.

The printer is very easy to use. The menu is intuitively designed and responds perfectly even when wearing gloves. I find the function that allows you to view the printing hours and select the language particularly practical.

An important point worth mentioning is that the printer offers a multilingual menu navigation, including of course in German. However, I noticed a few small inconsistencies or translation errors in some of the German translations. Nevertheless, the menu options are usually clearly worded and easy to navigate.

► Operation

As soon as the lid of the GKtwo is closed, the printer works extremely quietly. The fan is only slightly louder when the lid is open - this is probably due to the activated carbon filter. The filter is plugged into the back of the printer, which gives the impression of slight instability, but does not affect functionality in any way.

► Lid opens upwards

The ability to lift the lid upwards without having to remove the cover separately is both practical and time-saving. However, a damper for the lid would be a useful addition, especially if you only have one hand free and want to close the printer.

► Desirable changes for the future

Only small improvements regarding the loud activated carbon filter and the possibility of self-levelling could further round off the already excellent overall package.

Conclusion

In summary, I can unreservedly recommend the resin printer. It impresses with its extensive range of accessories, easy operation and attractive design. The models printed with GKtwo have fantastic quality and are not plagued by adhesion problems. With its large tank volume, the resin printer is ideal for a wide range of printing projects.

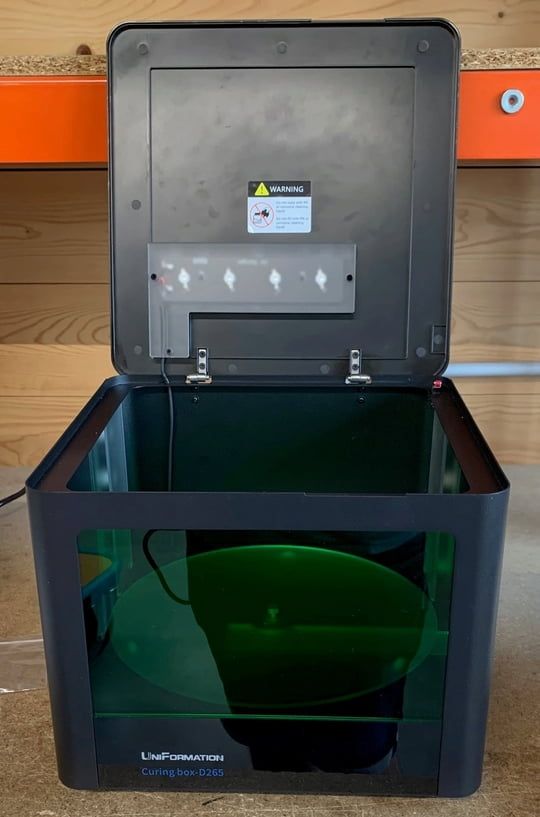

UniFormation Curing Station

Thanks to its sturdy workmanship and attractive design, the Curing Station fits perfectly with the GKtwo 3D printer. It offers everything that is expected from a high-quality curing station. The internal dimensions are generous and provide enough space for a variety of 3D-printed objects.

Thanks to its sturdy workmanship and attractive design, the Curing Station fits perfectly with the GKtwo 3D printer. It offers everything that is expected from a high-quality curing station. The internal dimensions are generous and provide enough space for a variety of 3D-printed objects.

► Curing

Uniform exposure ensures efficient and thorough curing of models, resulting in improved surface quality and strength.

My only point of criticism here is the limitation in the height of the objects to be cured. Although my 3D printer has a print volume of 228 x 128 x 245 mm, I can only place objects with a maximum height of 150 mm into the curing station. This means that I either have to move larger objects or can't get them into the station at all. What a shame!

► Using the Curing Station

Overall, operating the Curing Station is simple and intuitive. Most functions are self-explanatory and do not require lengthy training. However, I find the gear symbol for setting the time a bit unnecessary and would have liked it better if you could set the time without clicking. But that's just a small note.

► Smart features

Thanks to a door detection sensor, the curing process is automatically stopped as soon as the lid is opened. This is of course practical because you don't necessarily want to look at UV light.

Conclusion

I am extremely satisfied with the curing station. Apart from the slight limitation in height and the minimal criticism regarding the operation, I can unreservedly recommend the Curing Station from UniFormation.

UniFormation Ultra Sonic Resin Cleaner

The Resin Cleaner from UniFormation not only impresses with a beautiful design, which also visually matches the GKtwo 3D printer, but also with a stable structure and a generous capacity for the cleaning fluid.

The Resin Cleaner from UniFormation not only impresses with a beautiful design, which also visually matches the GKtwo 3D printer, but also with a stable structure and a generous capacity for the cleaning fluid.

► Slot for the build plate + cleaning basket

What I particularly like about the Resin Cleaner is the recess on the lid. It is designed to fit my 3D printer's build platform perfectly, which not only makes cleaning the printed objects incredibly easy but also saves time and effort. If you decide to remove the printed objects from the printing platform, that's no problem: a cleaning basket for storing the printed objects is also part of the contents of delivery.

► Hinged lid

The lid of the resin cleaner is easy to close and seal. This seal helps the ultrasonic cleaner work a little quieter. Although I still find the noise annoying, it is still pleasing that at least some noise reduction is achieved.

► Drain valve on the back

Another practical feature is the drain valve on the back of the device. When it's time to change the cleaning fluid, I can drain it easily and cleanly through the valve. This saves time and prevents possible spills or splashes.

► Operation

As with the Curing Station, I find the gear symbol for the time setting a bit unnecessary.

Conclusion

Overall, I am very satisfied with the resin cleaner. Features such as the recess on the lid or the drain valve make the cleaning process easy and efficient.

Latest reviews

-

4.0 (1)

4.0 (1)nice essentials PLA Basic Grey, 1.75 mm / 1000 g

- Made in Austria

- Bio-based plastic

- Excellent quality

$12.74 ($12.74 / kg)Delivery by March 02

-

$18.63 ($18.63 / kg)

$18.63 ($18.63 / kg)Delivery by March 02

-

4.8 (10)

4.8 (10)Fiberlogy Matt PET-G Black, 1,75 mm / 850 g

- Matt finish

- Easy to print

- Resistant to acids, salts, alkaline substances

$26.46 ($31.13 / kg)Delivery by March 02

Magazine Articles:

Discover 3DJake:

-

Delivery in 3 business days.

More than 10.400 products

We deliver worldwide to

more than 40 countriesSecure payments

with SSL encryption technology